Mitsubishi Heavy Industries Machine Tool Co., Ltd., a group company of

Mitsubishi Heavy Industries, Ltd. (MHI)(TOKYO:7011) based in Ritto,

Shiga Prefecture, is set to begin overseas marketing of its 3D

(three-dimensional) printer using its proprietary Directed Energy

Deposition (DED) process.1 The aim is to enhance recognition

and gain a foothold in the United States, which is driving the rapidly

growing global market for 3D printing. As a first step, MHI Machine Tool

will attend RAPID + TCT 2019, a trade fair for advanced additive

manufacturing technologies, held from May 20-23 in Detroit, in order to

showcase its new technologies essential for the practical application of

metal 3D printing, along with the monitoring feedback and local

shielding functions. These latter two functions are the world’s first

practical applications of new technology.

This press release features multimedia. View the full release here:

https://www.businesswire.com/news/home/20190516005371/en/

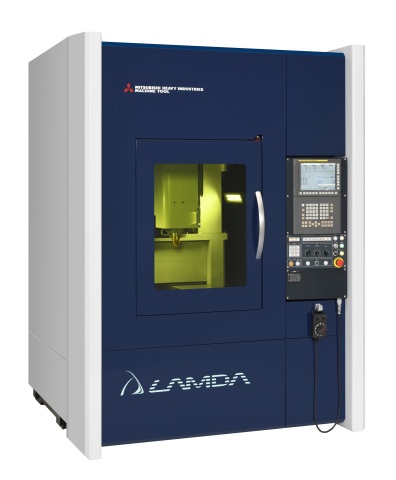

MHI Machine Tool “LAMDA 200” (Photo: Business Wire)

This metal 3D printer was developed by MHI Machine Tool based on the

results from a technology development project2 conducted by

the Technology Research Association for Future Additive Manufacturing

(TRAFAM), commissioned by the New Energy and Industrial Technology

Development Organization (NEDO). The entry model “LAMDA 200,” specific

for the manufacture of small prototype components, was launched in March

2019. In the proprietary DED process, powder is continually injected

from a nozzle, then melted and solidified by laser irradiation. Compared

to the powder bed fusion (PBF) process, in which material is formed by

rolling out and filling the metal powder in a tank (bed), molding speed

is more than 10 times faster, and with the elimination of the tank for

the metal powder, DED allows for the manufacture of larger objects not

possible with PBF. Further, the continuous supply of material eliminates

the need to switch materials during the molding process, allowing for

the forming of composite material components from numerous different

metal powders. Going forward, this process is expected to be applied for

the development of functionally gradient materials joining together

components made of different materials. Along with this technology, MHI

Machine Tool is on the verge of achieving practical application of

monitoring feedback and local shielding functions, which will enhance

the stability of molding quality and allow for the formation of large

components.

Specifically, the monitoring function is a system that uses a camera and

sensors to monitor the printing status. The feedback function then

utilizes the monitoring results to control the laser output and other

printing conditions in real time, stabilizing the melting and

solidification of the metal. Previously, the optimal printing conditions

for different shape were determined through trial and error. The

monitoring and feedback function optimizes the printing conditions

automatically, eliminating the need for trial and error. The shielding

function removes oxygen from the ambient environment around the nozzle

during DED process, preventing oxidation of the melted metal. The local

shielding function allows for printing of materials such as titanium and

aluminum, which are averse to oxidation, in an air environment without

the use of a chamber. Use of these functions also eliminates the

restrictions on the size of 3D printing objects, making the system

applicable for the manufacture of larger components, which has been an

issue in such industries as aerospace. MHI Machine Tool will present the

development results of its monitoring feedback and local shielding

functions at RAPID + TCT 2019.

Demand for high-performance components made from a variety of materials

is projected to increase worldwide, particularly in such industries as

aerospace, where components are continually being made lighter, and the

automotive industry, which continually demands cutting-edge

technologies. MHI Machine Tool is resolving the issues with practical

application of metal 3D printing, and going forward, through proposals

for formation processes for high-performance materials, will focus on

raising awareness and uncovering demand for metal 3D printing. With the

new approach of metal additive manufacturing, we will broaden the scope

of manufacturing that has reached the limits of conventional cutting and

grinding processing technologies.

|

Notes |

||

|

*1: |

Directed Energy Deposition (DED) is an additive manufacturing |

|

|

*2: |

The new 3D printer applies the results of the development |

|

About Mitsubishi Heavy Industries Group

Mitsubishi Heavy Industries, Ltd. (MHI), headquartered in Tokyo, is one

of the world’s leading industrial firms with 80,000 group employees and

annual consolidated revenues of around 38 billion U.S. dollars. For more

than 130 years, the company has channeled big thinking into innovative

and integrated solutions that move the world forward. MHI owns a unique

business portfolio covering land, sea, sky and even space. MHI delivers

innovative and integrated solutions across a wide range of industries

from commercial aviation and transportation to power plants and gas

turbines, and from machinery and infrastructure to integrated defense

and space systems.

For more information, please visit MHI’s

website: www.mhi.com/index.html

For

Technology, Trends and Tangents, visit MHI’s new online media SPECTRA:

spectra.mhi.com

View source version on businesswire.com: https://www.businesswire.com/news/home/20190516005371/en/